What is the unit?

A gearbox for a car with a transverse engine was presented for the first time at the Avtoprom-84 exhibition. It was installed in the engine compartment of the VAZ-2108, the main exhibit.

And since then, all gearboxes for front-wheel drive vehicles have been designed according to the same scheme.

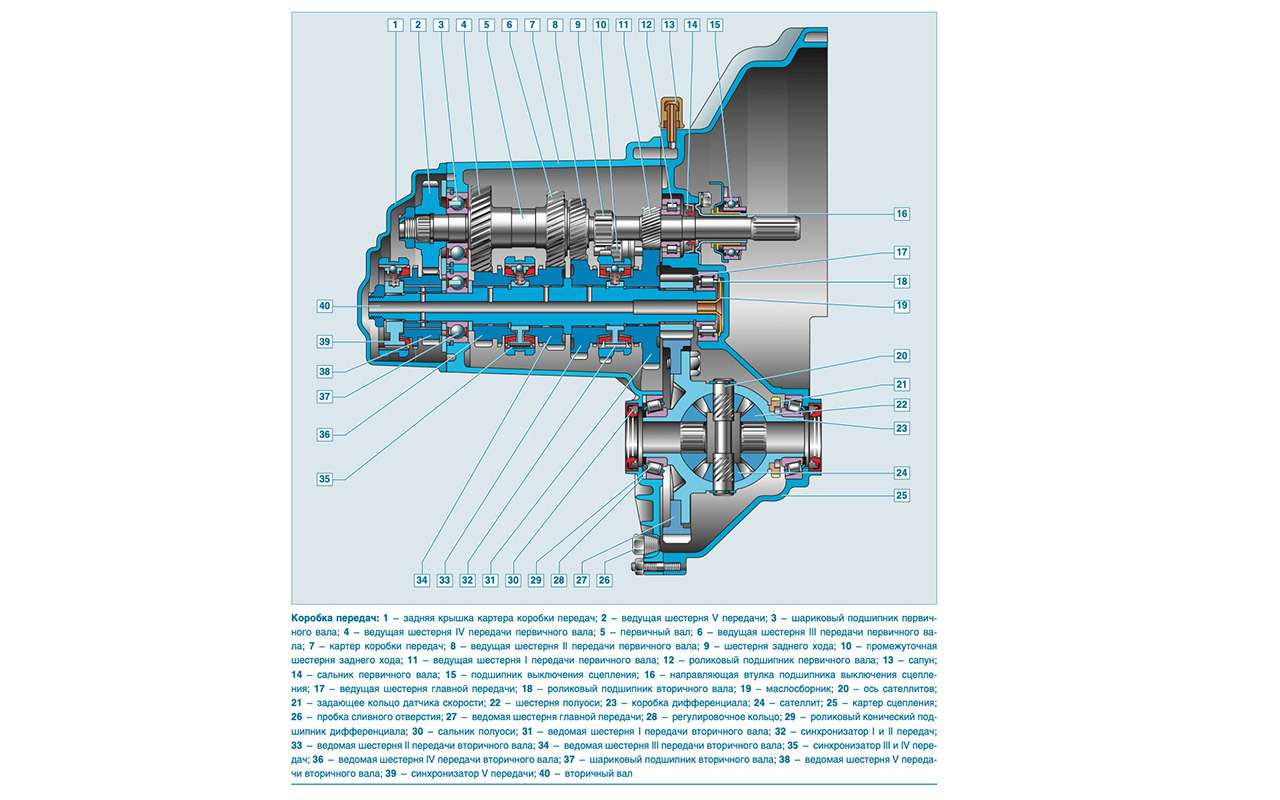

Gearbox – two-axis. The input shaft is a set of four forward helical gears and one rear gear made integral with the shaft. Then a fifth gear was mounted on the free end of the input shaft.

The output shaft carries synchronized clutches for engaging all forward gears and the corresponding gears. At the front end of the shaft is the main gear drive gear. It drives the driven gear mounted on the differential box.

The design of the box has generally not changed for 40 years.

There are many drawbacks to a box that is too large. Some have been eliminated with upgrades, others have been made worse by the arrival of more powerful engines.

Clumsy controller

Before the upgrade, there was traction in the gearbox control. And he did not differ in ease and clarity of switching.

Drivers in particular have accidentally engaged reverse gear instead of first, leading to embarrassing accidents.

In addition, all the vibrations and vibrations came from the power unit to the lever.

All problems disappeared when a new cable drive appeared.

Cannot add transfer

The architecture and the small center-to-center distance between the primary and secondary shafts of the box, designed for low-power engines, do not allow to make a “six-speed”.

Six-speed boxes have long been installed even on inexpensive cars. We need such unity and promising Frets. Power and speed increase, more and more roads appear on which you can drive fast. Overdrive helps reduce fuel consumption, noise and emissions at high speeds.

Weak for modern engines

The small center distance of the shafts causes the use of small diameter gears and weak bearings. Due to increased loads, bearings sometimes run no more than 50-70 thousand km.

The differential was also problematic. On old carburetor engines, the resource was sufficient. And today, due to the increased power, the satellites sometimes burst, cut off the differential shaft and even split the crankcase.

Increased wear of synchronizers

Second gear synchronizers wear the fastest.

The reason is a large gap in the gear ratios of first and second gear. And the synchronizer is forced to equalize a serious difference in the speed of the primary and secondary shafts.

Especially for drivers who like intense acceleration from a traffic light.

With the next modernization of the box, the factory introduced two-cone synchronizers. It got better, but the resource didn’t increase dramatically.

Noise at work

Gearboxes mounted on commercial vehicles sometimes differ greatly in noise levels during operation. Some cases just bother driving in certain gears. Usually – on the fifth.

But there are also relatively quiet specimens. All this testifies to the low production level of gearbox parts and the instability of quality.

Improvements are not good

In the last modifications of the gearbox, the oil dipstick disappeared – it became more difficult to control the level. This means that they perform this action less often.

And the gears and bearings of the fifth gear especially suffer from a lack of lubrication.

Instead of steel shift forks, they started using silumin forks with plastic liner. These brake pads burn out almost immediately at low oil levels and high temperatures.

By the way, the forks of the new design are three times more expensive than the previous ones.

To avoid such malfunctions, it may be advised to keep the oil level in the unit slightly above the recommended level.

Everything is concentrated in one unit: the gearbox. It has been installed on cars for decades. But neither time nor countless upgrades have healed some childhood sores.

Source: Z R

Anika Rood is an author at “Social Bites”. She is an automobile enthusiast who writes about the latest developments and news in the automobile industry. With a deep understanding of the latest technologies and a passion for writing, Anika provides insightful and engaging articles that keep her readers informed and up-to-date on the latest happenings in the world of automobiles.