Why is blocking necessary?

The torque converter is an integral part of classic automatic machines and almost all CVTs. It had no clogging until about the 1990s. Everything was simple, reliable, durable.

But the power loss was huge. Accordingly, the fuel consumption of cars with an automatic transmission was significantly higher than that of the same models, but with a manual transmission.

Therefore, taking care of increasing efficiency, the designers developed a mechanism that is a clutch that works in the torque converter. This friction mechanism is more commonly referred to as a clutch.

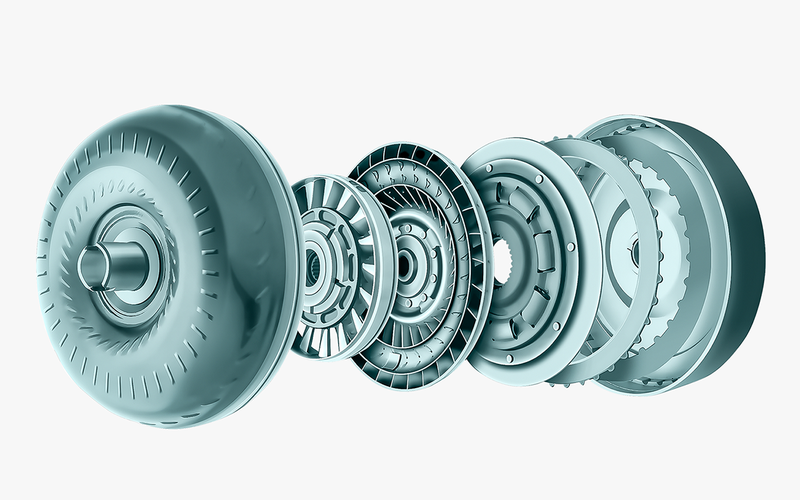

The main components of a modern torque converter: 1 – freewheel; 2 – blocking clutch; 3 – hydraulic part (pump, turbine wheels and reactor)

The clutch provides locking – that is, it engages the pump and turbine wheel of the torque converter. In this case, a rigid connection of the crankshaft of the engine and the input shaft of the gearbox is created.

But that’s how locks worked on old boxes. In modern units, the automatic transmission control unit, by adjusting the fluid pressure, can control the actuation torque. And most importantly – the compression force of the clutch plates. This allows the clutch to run in slip mode.

Pros and cons

Advantages lock-up torque converters have two:

- lower fuel consumption and higher efficiency

- precise (electronic) torque control, smoothing out shocks.

cons – Lake.

- During hard accelerations of the car, the torque converter lock-up clutch works very hard to smooth out the jerks. And wears out quickly.

- Wear products enter the gearbox together with the fluid and contaminate the valve body. This can lead to the failure of the control valves.

- The worse the valve that controls the torque converter lockout works, the more the clutch wears out. The amount of wear products in the fluid increases.

How to save the machine?

If you want to extend the life of a modern automatic transmission or CVT, you shouldn’t accelerate “to the ground” at every stop light.

- Regular replacement of the working fluid (along with filters where possible) helps to increase the gearbox’s resource.

- “Behind the wheel” can now be read in Telegram.

Vote – win Lada!

Take part in the “Behind the Wheel” Grand Prix vote and help us choose the best car novelties of the year.

As a thank you for the time spent, we raffle among the participants in the survey three frets. There is an opportunity for everyone who completes the questionnaire earlier February 28, 2023.

COMPLETE THE 2023 DRIVING GRAND PRIX QUESTIONNAIRE

Source: Z R

Anika Rood is an author at “Social Bites”. She is an automobile enthusiast who writes about the latest developments and news in the automobile industry. With a deep understanding of the latest technologies and a passion for writing, Anika provides insightful and engaging articles that keep her readers informed and up-to-date on the latest happenings in the world of automobiles.