Boxes of the 6T30 series are designed to be combined with engines of small displacement and small power. They can be found on Chevrolet Aveo, Cruze, Orlando, Cobalt and Lacetti models, as well as Daewoo Gentra.

6T40 units are designed for heavier and more powerful vehicles – Chevrolet Captiva, Cruze and Lacetti.

6T45E are installed on front-wheel drive and all-wheel drive vehicles up to 3.2 liters, including, for example, Opel Antara.

The first digit (6) in the designation indicates the number of gears. The letter T means that these boxes are coupled with motors mounted transversely to them. And the numbers 30, 40, 45 are a class in terms of torque transmitted.

But no matter what model these boxes are installed on, all owners face the same problems.

Overheating of the working fluid

In the summer, in traffic jams and during intensive driving, the temperature of the fluid rises to over 100°C. And when overheated, ATF fluid degrades quickly. To avoid this, keep the air conditioning heat exchanger and engine radiator clean (by the way, you can wash them yourself).

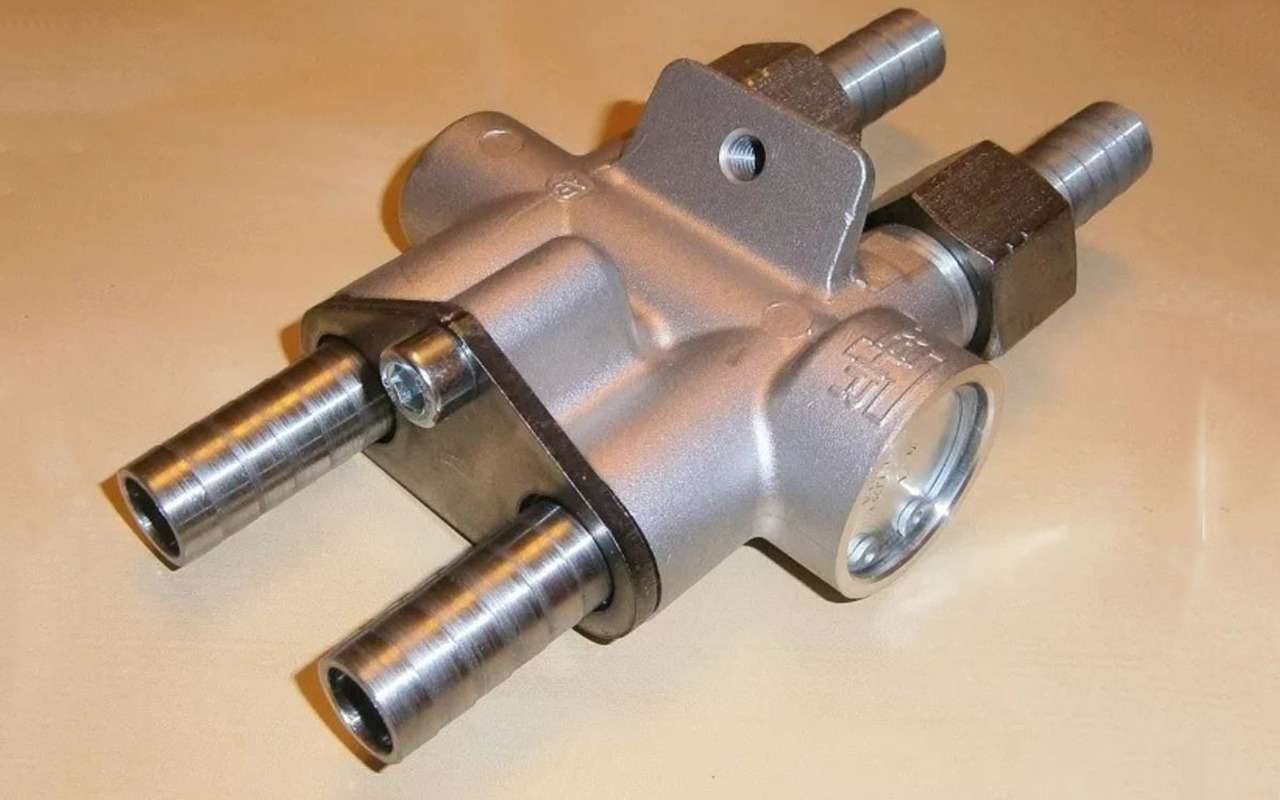

If the box often works under high load, it is better to install an additional radiator for the machine. In addition to the radiator, you also need a thermostat that ensures that the liquid does not get too cold in winter. Installation of such a kit will cost as much as 15 thousand rubles.

Kits are available for installing a radiator for automatic transmissions. True, the thermostat is not included.

Complex design

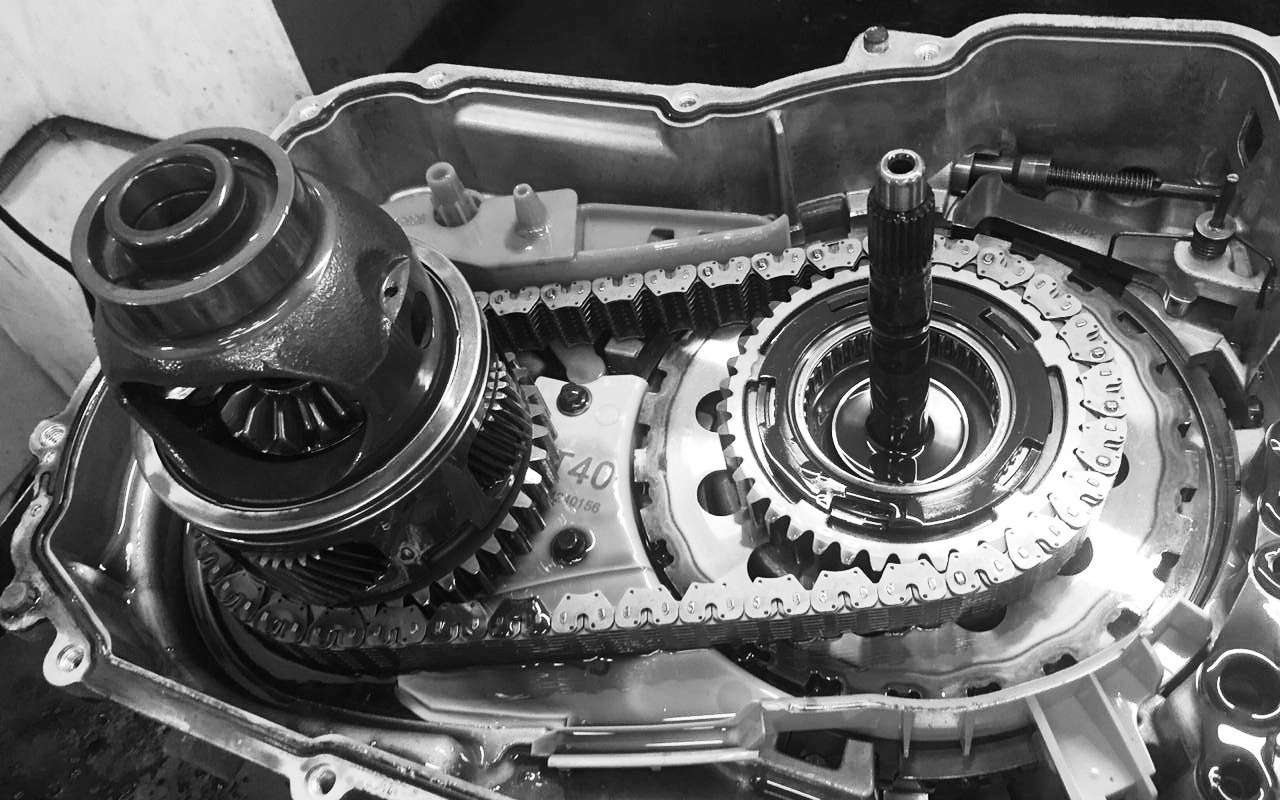

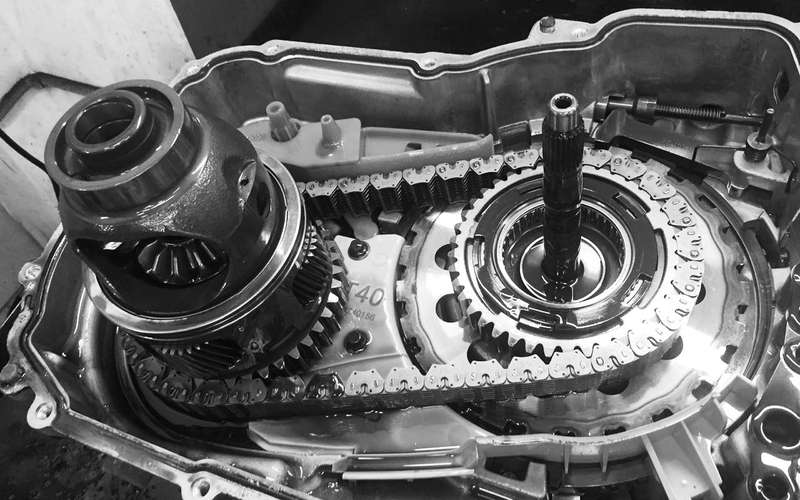

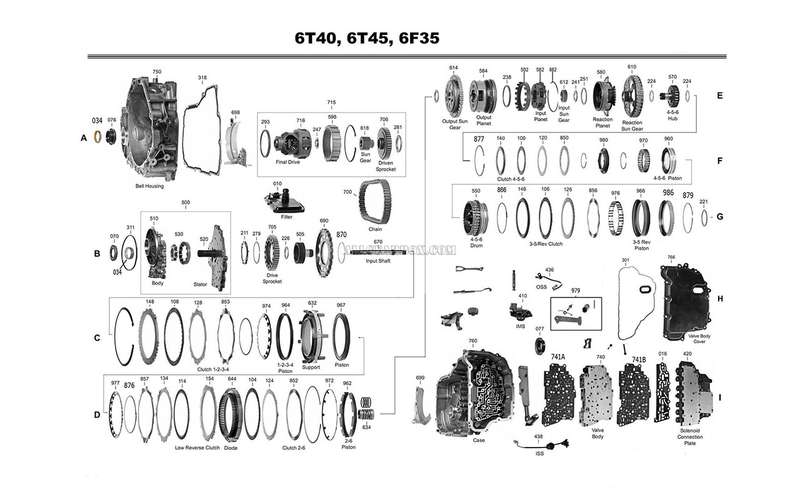

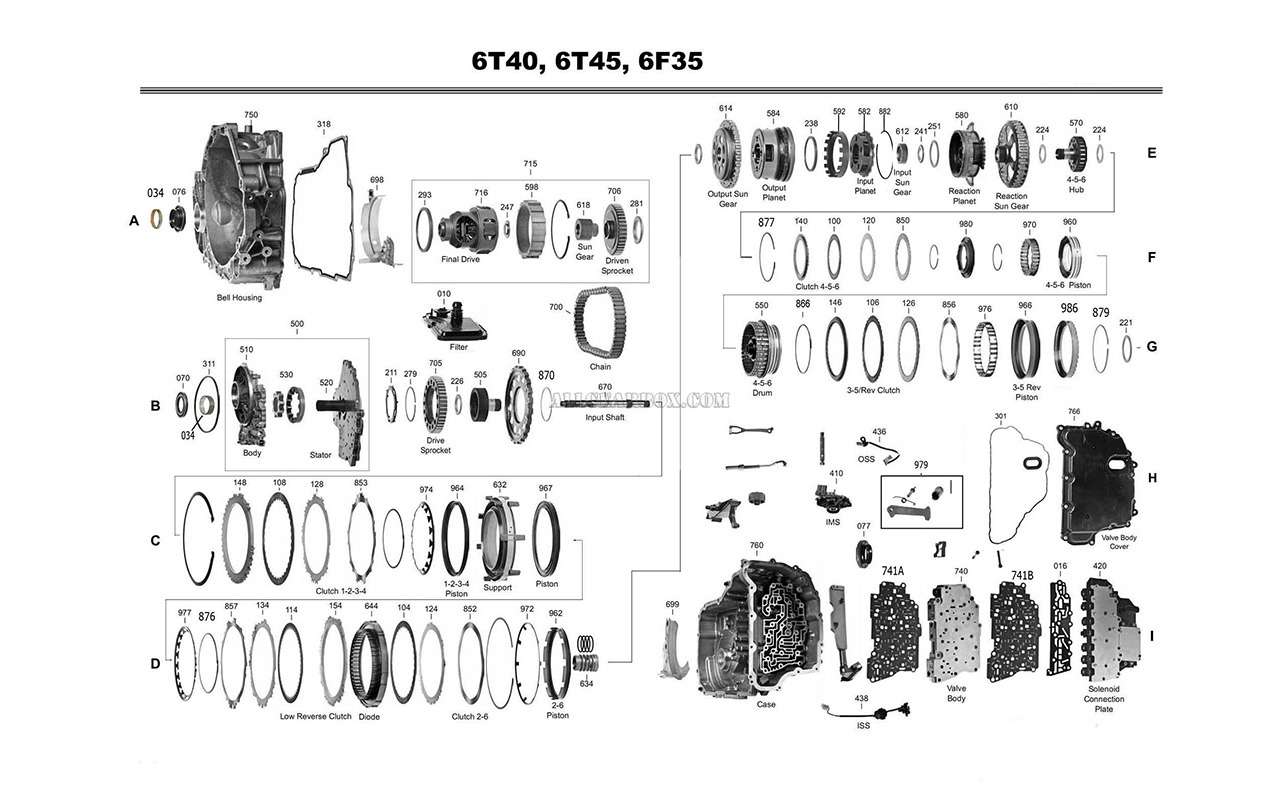

Chain drives are rare in classic hydromechanical automatic machines.

The vast majority of transverse automatic transmissions are managed with cylindrical gears.

But in the GM box, the torque from the planetary gear sets to the differential is precisely transmitted by a multi-row multi-row chain. And such chains wear out quite quickly (there are a lot of joints). Numerous wear products are carried through the box by fluid and interfere with the operation of other parts and assemblies.

Malicious unification

To reduce production costs, designers united gearboxes for engines that differ significantly in power. This leads to the fact that in compact cars the box is slightly overweight, but has a good margin of safety, but in large cars the resource is insufficient. The mileage before overhaul is 120-150 thousand km, which is not enough for a hydromechanical machine.

Premature pressure loss

Increased vibrations caused by the transmission of maximum torques break the shaft sleeves. Due to worn bushings, ATF begins to leave the working cavities. The pump performance is not sufficient and the electronic control system instructs the solenoids to open the section further and further. As a result, the clutches begin to slip. Wear products enter the fluid and disable the valve body.

Problems with the valve body

This design was modernized several times, but problems continued to haunt him. When working with a superheated liquid (up to 120 ° C), which contains a lot of ferrous particles, the shaft speed sensors begin to work. Their principle of operation is based on the Hall effect, and the steel “sawdust” adhering to them interferes with their work.

First, the gears from fourth to sixth begin to slip, and then the problems increase.

Simple advice: change the fluid and filter more often to extend the life of the box.

And a few tips that will help prevent problems during the repair and operation of these machines.

Check torque converter

When repairing automatic transmissions of the 6T30 / 6T40 / 6T45 family, do not forget about the friction discs in the torque converter. After all, almost any malfunction of the box leads to the ingress of a large amount of chips into the working fluid, which quickly wears out the clutch.

Forget chip tuning

All boxes of the family do not have a large torque margin. Therefore, they only serve well if the car is driven carefully and measuredly. Forcing the engine to models with such automatic transmissions is contraindicated. Otherwise, you will have to repair the machine much earlier than the specified period. And it is possible that the engine too.

Don’t forget to subscribe

Interesting facts, news from the automotive world, expert opinions and our expertise – all this is in each issue of the magazine “Behind the wheel”. The surest way not to miss anything is to subscribe to a magazine that is delivered to your home every month.

You can subscribe to the magazine within minutes via this link.

Vote – win Lada!

Take part in the Behind the Wheel Grand Prix vote and help us choose the best car novelties of the year.

As a thank you for the time spent, we raffle among the participants in the survey three ferrets. There is a chance for everyone who completes the questionnaire earlier February 28, 2023.

COMPLETE THE 2023 DRIVING GRAND PRIX QUESTIONNAIRE

This six-speed automatic, developed by General Motors, appeared in 2007. They can be found on Opel, Chevrolet, Daewoo and even rare SAAB and Buick cars.

Source: Z R

Anika Rood is an author at “Social Bites”. She is an automobile enthusiast who writes about the latest developments and news in the automobile industry. With a deep understanding of the latest technologies and a passion for writing, Anika provides insightful and engaging articles that keep her readers informed and up-to-date on the latest happenings in the world of automobiles.