The cause of every sound is vibrations, vibrations. In the past, unlubricated carcasses often cracked. After that, every now and then the wheel hub was “welded” to the axle for a while, and then abruptly broke off, causing a creak. Much the same thing happens in modern cars, when the brake pads continuously stick to the disc or drum for a split second during braking and then break back.

How to fight?

The axles of the carts were periodically lubricated and the creaking disappeared for a while. But the working surfaces of the brake pads cannot be lubricated: we will be left without brakes. But you can’t let the pads make free vibrations.

In practice this is done in different ways.

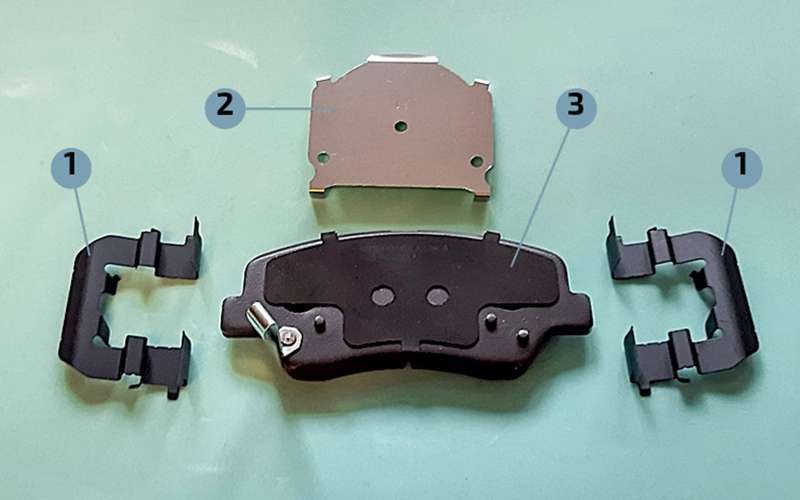

- In particular, anti-cracking pads, of metal or of vibration-damping material, are applied to the non-working (back) surfaces and chamfers are applied to the workers. In the latter case, the working area is reduced, but the developers deliberately go for it, shifting the resonant frequency of oscillations to the region of the inaudible range.

On some vehicles, brake pad vibration and noise are reduced by installing a coiled spring that compresses the outer brake pads.

- Another technique is to make one or more slots on the working surfaces of the pads. Sometimes, to dampen vibrations, a special plate is installed, which is attached to the back of the block with legs. In some cases, different parentheses are used for the same purpose.

Many pads have acoustic wear indicators. Rather, they intentionally emit an obnoxious screeching under braking when the pad is too thin. This is the signal to replace the pads.

We change in advance

However, worn pads themselves can make a distinctive squeaking sound.

You can not delay the replacement: such pads no longer slow down. In addition, their extreme wear causes a deformation of the pistons extending from the brake cylinders to the maximum value. Therefore, do not wait for the maximum output of the pads – it is better to replace them proactively, then they will not make any sound.

Choose quality

Pads often start to make noise when an unscrupulous manufacturer puts too many iron chips in their friction mixture, which, unlike high-tech compounds, only costs pennies. Such pads will slow down “sharper”, but the discs will slide like a cat butter, which will quickly result in high spending. In addition to noise, they will overheat more easily – it will be more difficult to dose the braking force.

Therefore, when replacing brake pads, it is usually recommended to pay attention to branded products that have a good reputation in the market. However, it makes sense that owners of mass-produced cars rely on budget products from well-known domestic suppliers, without waiting for the cracking of metal on metal.

All brake pads are typical consumables, which the owner only benefits from regular replacement with new ones.

You can choose the pads for your car and find the nearest sellers from this link.

- We checked the brake pads: every third is life-threatening!

- “Driving” can be read in viber

Why do car brakes squeak and how to deal with it? We tell.