If you want to know the secrets of the universe, think in units of energy, frequency and vibration.

Nikola Tesla

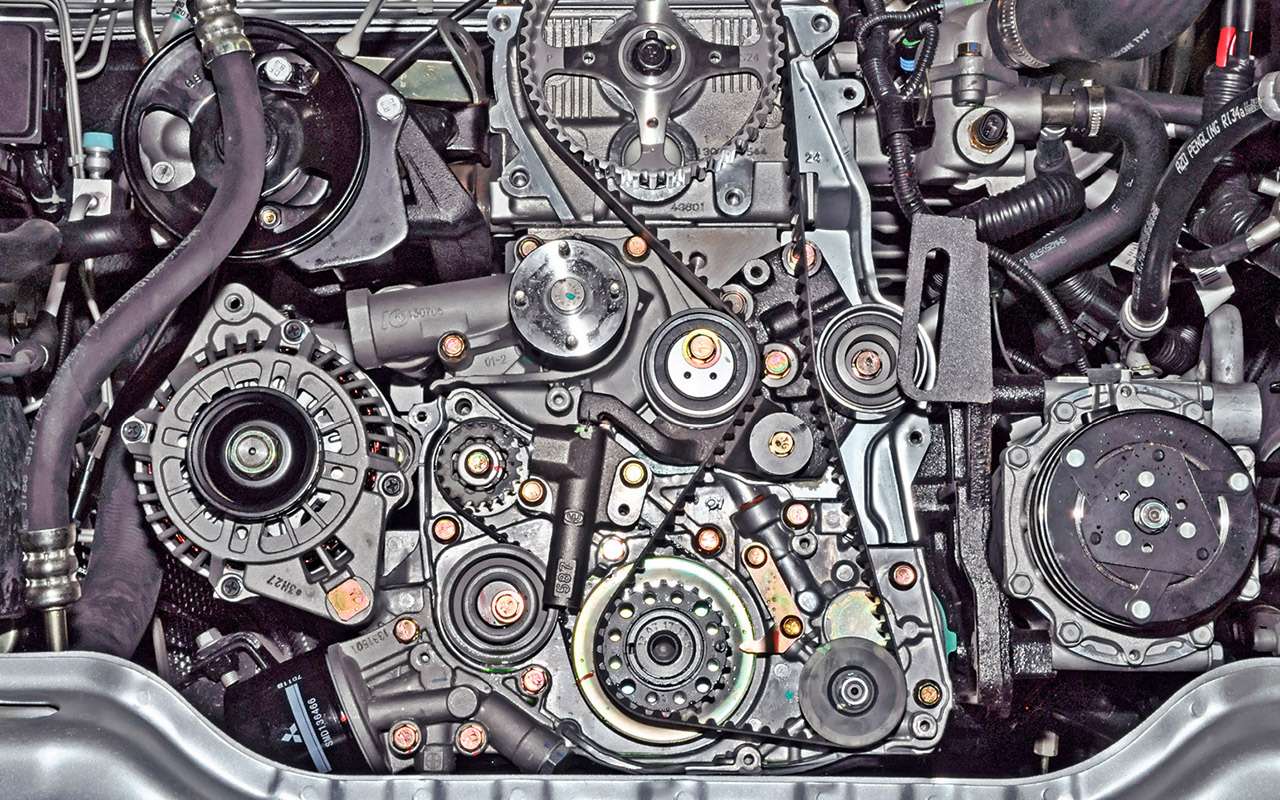

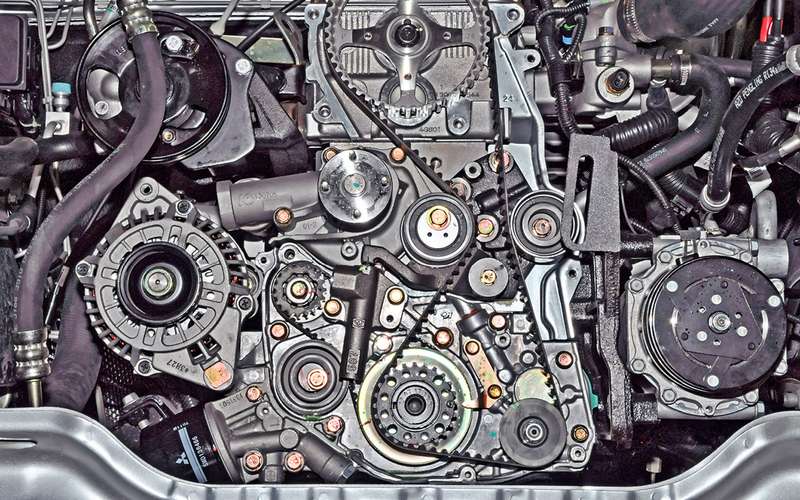

An internal combustion engine is a collection of solid parts that move with gears. If it is possible to design a motor in such a way that all forces and moments balance each other, a self-balancing motor is created. But in practice this is not always the case.

In any case, take the crankshaft – all so “unequal”, and even hung with connecting rods. The mass of the lower head of the connecting rod together with the connecting rod pin can be balanced by counterweights on the crankshaft. And in the engine quite large masses – the pistons and the upper heads of the connecting rods – move back and forth. This causes the appearance of forces that shake the engine along the axis of the cylinder. They can be divided into inertial forces of the first and second order.

Forces of inertia arise because the piston does not move evenly in the cylinder, but reaches its maximum speed in the middle of its stroke and stops at the top and bottom dead points.

- The first order inertial forces are approximately proportional to the mass of the reciprocating parts, the radius of the crank, the square of the angular velocity of the crankshaft, and the cosine of its angle of rotation.

- The second-order inertial forces are proportional to the mass of the reciprocating parts, the squares of the crankshaft’s angular velocity and radius, the cosine of twice the crankshaft’s angle of rotation, and are inversely proportional to the length of the connection fishing rod. Engines with long connecting rods have almost no need to compensate for the second-order inertia forces, but are structurally unfavorable due to the increase in the height of the cylinder block.

To balance!

Balancing a single or two cylinder engine.

Single- and twin-cylinder engines with parallel pistons can be balanced against first-order inertial forces by two balance shafts with asymmetrical masses that rotate with crankshaft speed. The most famous example for us is the Oka engine.

The second-order inertia forces are compensated by two displaced-mass shafts, which rotate twice as fast as the crankshaft.

In three-cylinder inline engines with crankshafts at an angle of 120 degrees, the inertial forces of the first and second order are balanced. But at the same time, the moments of the inertial forces of the first and second order will be out of balance. The moments of the inertial forces of the first order are compensated by a shaft that rotates with the speed of the crankshaft. Other disturbances are neglected – therefore, in practice, almost all three-cylinder engines have modes in which “itching” is felt.

In four-cylinder inline engines, all forces and moments are in equilibrium, except for the second-order inertia forces. If the engine’s pistons are not very large (that is, with a displacement of up to about two liters), the second-order inertia forces are negligible and are neglected. With a larger size, it is necessary to install balance shafts.

The perfectly balanced engine is the in-line “six” and its derivative – the V12 engine.

The balance of the motors from the moment of use and wear does not change. If the balance shaft drive at the engine failed, it most likely won’t have long to live. For example, in Korean four-cylinder engines, the balance shafts are driven by an oil pump and in some Mitsubishi engines by a timing belt.

|

Signs of motor self-balance – this is the equality to zero of the total inertial forces of the translationally moving masses (caused by acceleration with a frequency equal to the crankshaft speed of the engine and twice the rotational speed – these are the inertial forces of the first and second order) and the total centrifugal forces. To this are added the moments of these forces acting with respect to the center of the crankshaft in the plane of the crankshaft axis. There are a total of six boards. |

You got the crowd wrong

In an ideal engine, the masses of all parts of the same name are the same, all rotating parts are in equilibrium, or vice versa, the calculated imbalance, but exactly sustained. If these conditions are not met, the motor will vibrate at the frequency of the element that is out of balance.

Most commonly used problems arising from wear of certain parts For example, a strong vibration of the engine is caused by crankshaft pulleys with a rubber damper when it is destroyed. Destroyed dual-mass flywheels can have the same effect.

You can contribute your share illiterate engine repair For example, it is important to mount pistons with a minimal difference in mass (preferably no more than one gram). Of course, during repairs, it is necessary to accurately install the balance shafts – otherwise the power unit may dance instead of reducing vibration.

The imbalance can even lead to inaccurate grinding of the crankshaft to the repair sizewhen the crankpins of a four-cylinder engine are not exactly 180 degrees.

Where do the vibrations come from?

The most common cause of increased engine vibration is the inconsistency in the operation of the cylinders. The worst work of one or more cylinders leads to the crankshaft starting to rotate unevenly – the engine will start to vibrate. In the simplest case, the engine “troits” – this is what drivers of cars with a four-cylinder engine, in which one cylinder did not work, always said.

The influence of one cylinder on the functioning of the engine is very noticeable, because we do not lose a quarter of the power, but even more through pumping losses and friction losses. Add here the unevenness of the flashes – and here comes the most unpleasant shaking. But some negligent drivers of the eight-cylinder ZIL-130 were able to drive the entire service with a stationary cylinder. If there are many cylinders, the loss of one is not so noticeable.

Who messed up the cylinder?

Abnormal operation of the cylinder can have various causes. Let’s look at them in more detail.

- No (or low) compression

There can be many reasons for loss of compression. For example, piston burnout, expressed in a hole in the bottom or in the area of the piston rings.

- Blown valve is the appearance of an opening through which gases can escape freely, even when the valve is pressed against the seat.

A burnt cylinder head gasket also leads to a lack of compression, especially on engines with old, thick metal-asbestos gaskets.

If the compression is maintained, but drops noticeably, the cylinder will also not function properly at full strength and thus cause vibration. The reasons are lifted cylinders or stuck rings, valves that do not close properly and the cylinder head gasket that starts to burn out.

- Lack of fuel supply

The nozzle may fail completely and then the cylinder will not work at all. And it will not work well with a nozzle in which the atomizer is clogged. It will be less noticeable on a port-injected engine and much more noticeable on a direct-injection or diesel engine.

- No spark or poor sparking

Interruptions in sparking can be caused by a malfunction or serious fouling of the spark plug. The same effect is achieved by broken or leaking ignition coils and high voltage wires.

- Wrong air supply

One of the cylinders may be getting too little or too much air. Little – when the valve is very misaligned or if there are problems with the valves that control the length of the intake tract. A lot of air gets in when the intake manifold gasket is damaged where air is supplied to the cylinder.

Symmetry needed!

The motor is a symmetrical mechanism. No matter how many cylinders it has, they should all work the same and smoothly. Otherwise it will vibrate.

- The American Cyclo automotive chemicals and SUPROTEC additives help maintain the vehicle’s components and assemblies in good condition.

- Read how to properly maintain a car in the books of the publishing house “Behind the wheel”.

- “Driving” can also be read on Viber.

The motor vibrates because it was designed that way, or because of a malfunction. Experts “Behind the wheel” separated one from the other.