Two important parameters of a battery are important for reliable engine starting: capacity and starting current or cold starting current. Capacity, in simple terms, indicates how much electricity a battery can store. Cold crank flow demonstrateshow confidently the battery will run a frozen engine in cold weather. Today we will tell you how the manufacturer checks these and other characteristics of the batteries coming off the assembly line. The tests were carried out on professional equipment in the test laboratory of the Kursk Battery Plant. During the battery test, we also decided to test the performance of the popular Midtroni portable tester.cs EXP1000.

We control the capacity

Capacity is nominal and reserve. Both nominal and reserve capacity are listed on the battery label. Nominal is measured in Amp Hours (Ah) and Reserve is measured in minutes (min). The hero of our tests, the battery PROS nominal capacity 60 Ah.

The requirements for batteries and their test methods in Russia are regulated by GOST R 53165 – 2020. The battery under test must be new – no more than 45 days can pass from the date of release. Before starting the tests, it must be fully charged.

When testing for nominal capacity, batteries are immersed in a water bath with a temperature of 25 ± 2°C.

Batteries in water baths when tested for nominal capacity

The test procedure according to the Russian standard is as follows: the battery is discharged with a direct current of 3 Amps to a voltage of 10.50 Volts, with the discharge time being controlled. The actual capacity is determined by the formula:

FROMf = t·ln

Where:

FROMf — actual capacity, Ah,

t — discharge time, h,

ln – the value of the discharge current, A

The discharge time of our battery was 20 hours 49 minutes. The calculated actual capacity – 62.45 Ah exceeds the stated capacity.

Determine the current

After determining the actual capacity, the test batteries were fully charged again, kept in a climate chamber for 24 hours at a temperature of minus 18 ± 1aboutC and tested with cold start current. This test was performed according to the European standard EN50342-1.

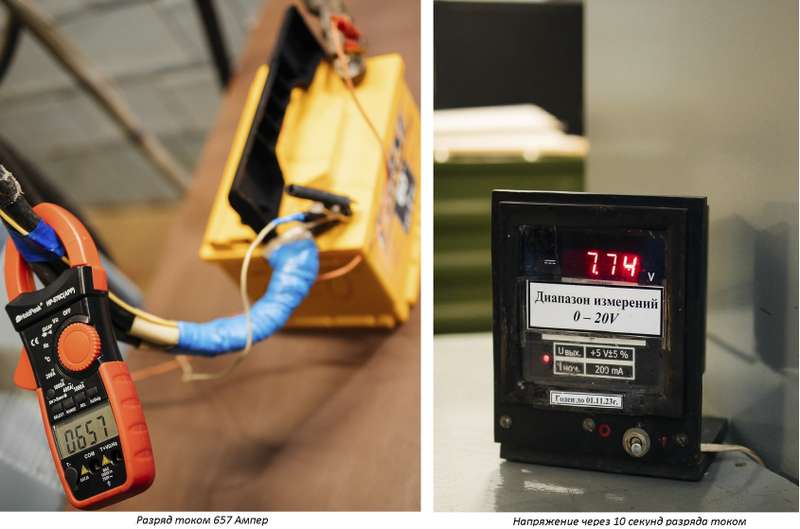

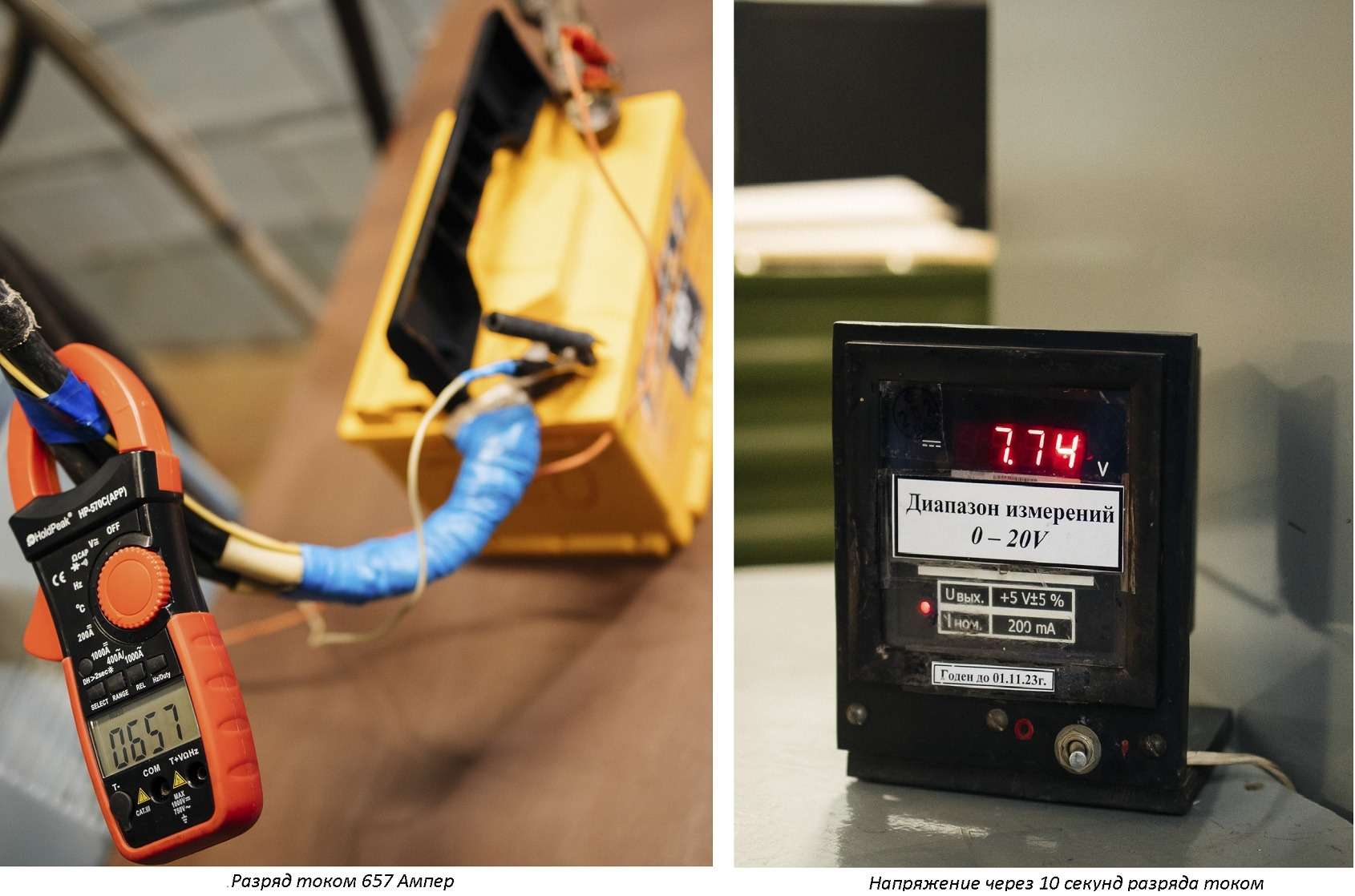

A cooled battery is discharged within 10 seconds at the current indicated on the product label. for battery PROS it is 640 amps. The voltage must not fall below 7.5 volts. During testing, the final voltage was 7.74 volts at an actual discharge current of 657 amps.

And this battery test was successful.

After a 10 second pause, the discharge was continued with a current of 384 A to a final voltage of 6.0 V. The total duration of the discharge was 92 seconds, which is higher than the required value (minimum 90 seconds).

We set the current at -30aboutFROM

Checking the cold scroll current at -30aboutC is only performed for batteries intended for use in cold climates. The test method is similar to testing at -18aboutC, but the temperature in the environmental chamber must be minus 29 ± 1°C, and the amount of current that the battery discharges is set by the battery manufacturer. The discharge current was set at 533 Amps.

The battery also successfully passed this test.

Check for strength

How durable is the battery case PROS in severe frost. The battery manufacturer, the Kursk Battery Plant, uses a special shock-resistant and frost-resistant propylene copolymer for the manufacture of cases, which must withstand shocks at a temperature of -50 °C.aboutS. It was so freezing in the room where the battery cabinets were.

Frozen hulls are tested for impact resistance on a special installation.

The battery case withstood impacts from four sides without cracking.

Power Test completed a series of winter battery tests PROS. All declared characteristics of a conventional battery taken off the assembly line were confirmed. It can be installed on a car – there will be no problems with starting the engine in winter.

The most important thing is the equipment

Midtroni testercs – a common device equipped with an infrared sensor that determines the surface temperature of the battery and can recalculate the amount of power taking into account the temperature of the battery.

At room temperature, the tester displayed the cold scroll current value closest to the true value.

But in the cold, the device began to underestimate the readings. Despite the fact that the battery passed the test with a cold scroll current of 657 A at -18aboutC, the measurement results Midtronics showed below the actual, and at -30aboutFROM the error has increased. These anomalies are likely related to coil surface temperature measurements and subsequent correlations in the cold crank flow calculation. The photo clearly shows that the temperature of the battery electrolyte is minus 30 degrees C, and the device shows that the surface temperature of the monoblock is only +3 degrees (photo 9)

Practice shows that such a device and similar testers can be used indoors at temperatures of 20-25aboutOf degrees. At low temperatures, the device recalculates the current value according to its internal algorithm and gives underestimated readings. Therefore, it is not recommended to use portable testers outdoors in winter. Serious battery testing should be done using professional equipment.

Advertising /Norgus LLC/4CQwVszH9pQPLyTkhLr

A well-maintained, maintained and charged battery is an important factor for trouble-free operation of any car, especially in winter.